The Latest Trends in Appliance Repair: Innovations and Techniques

Understanding the Shift in Appliance Repair

In recent years, the appliance repair industry has been experiencing a transformative shift, driven by technological advancements and innovative techniques. This evolution is not just about fixing what’s broken; it’s about improving efficiency, reducing costs, and enhancing the lifespan of appliances. As consumers become more environmentally conscious, the demand for effective repair solutions over replacements is increasing.

One of the most significant changes is the integration of smart technology into appliances. This has led to the rise of specialized technicians who are not only familiar with traditional mechanical issues but are also adept at handling software-related problems. This blend of skills ensures that appliances function optimally in today’s connected homes.

Innovative Diagnostic Tools

The introduction of advanced diagnostic tools has revolutionized how technicians approach appliance repairs. These tools use digital interfaces and wireless connectivity to quickly identify issues, reducing the time spent on troubleshooting. For instance, some modern diagnostic devices can interface directly with an appliance's software, providing real-time data on performance and pinpointing areas that need attention.

This innovation means faster service for customers and a more efficient workflow for technicians. The ability to diagnose problems accurately the first time around also minimizes unnecessary part replacements and reduces downtime for consumers.

Sustainability in Appliance Repair

Sustainability is becoming a core focus in the appliance repair industry. Companies are increasingly adopting eco-friendly practices by using parts that are recyclable or made from sustainable materials. Additionally, there is a growing emphasis on repairing rather than replacing appliances, which significantly reduces electronic waste.

Technicians are also being trained in sustainable repair techniques, ensuring that they can provide services that align with environmentally responsible practices. This shift not only benefits the planet but also appeals to a consumer base that values sustainability.

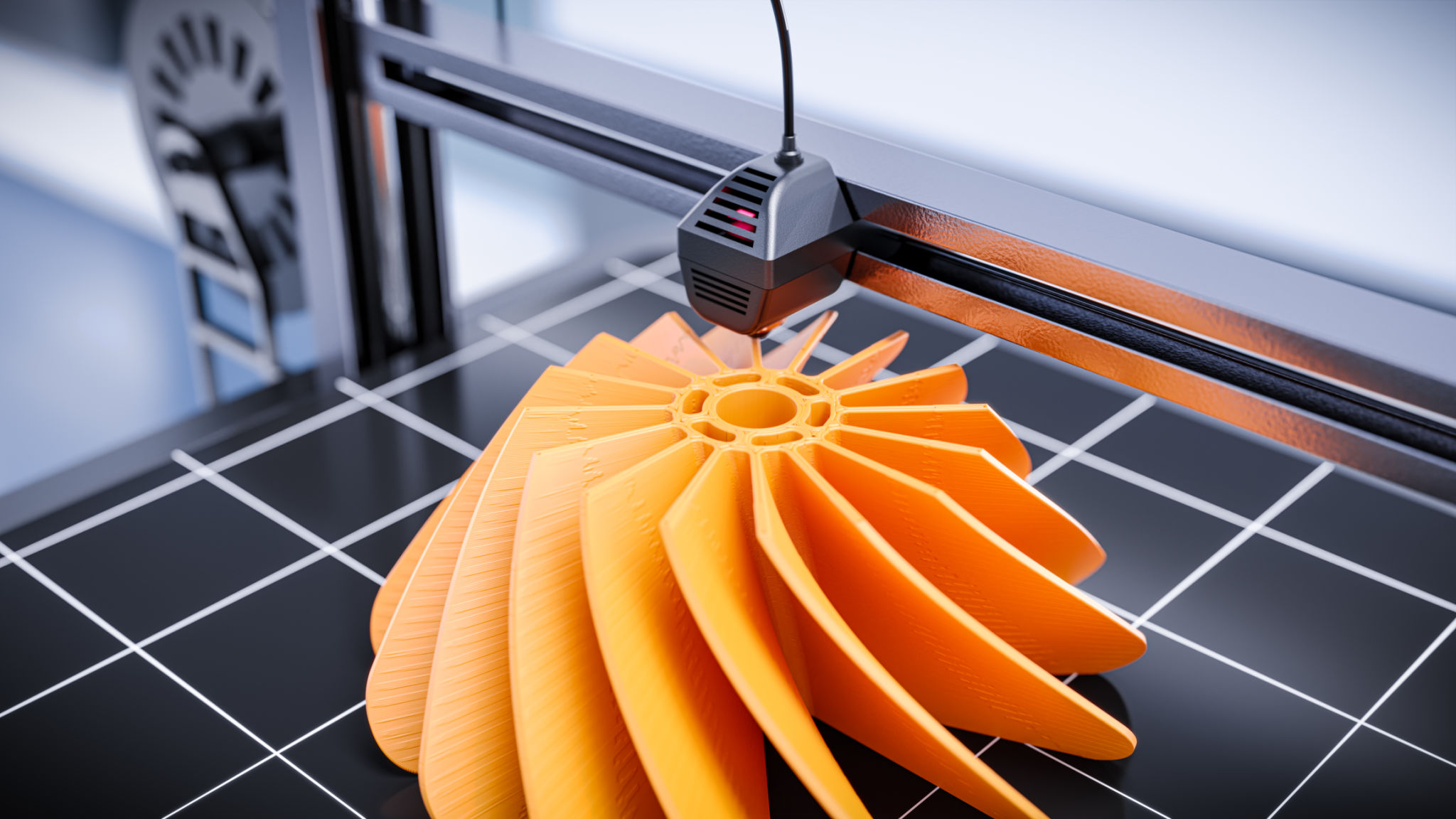

The Role of 3D Printing

One of the most exciting innovations is the use of 3D printing in appliance repair. This technology allows for the creation of custom parts on-demand, reducing the need to wait for specific components to be shipped from manufacturers. With 3D printing, technicians can produce precise parts tailored to an appliance's unique specifications, ensuring a perfect fit and function.

The ability to produce parts locally also contributes to sustainability by cutting down on the carbon footprint associated with transportation. Moreover, it empowers repair businesses to offer faster turnaround times for their customers.

Training and Certification Enhancements

As the industry evolves, so too must the skills of those within it. Continuous training and updated certifications have become essential for appliance repair technicians. Many training programs now include modules on smart technology, eco-friendly practices, and advanced diagnostics. This ensures that technicians remain at the forefront of industry developments and can provide top-notch service.

The importance of ongoing education cannot be overstated in an industry that is rapidly changing. By staying informed about the latest trends and technologies, repair professionals can maintain high standards of service and customer satisfaction.

Conclusion: Embracing Change

The appliance repair industry is in the midst of an exciting transformation. With innovations such as smart diagnostics, sustainable practices, 3D printing, and enhanced training programs, repair services are becoming more efficient and environmentally friendly. As these trends continue to develop, both technicians and consumers stand to benefit from improved service quality and a reduced environmental impact.